Boat Repair & Maintenance Services

Maintenance & Repair Services

Onyx services are designed to make your experience on the water the best it can be. We understand that boat maintenance can become time-consuming and a hassle at times. Our goal is to provide a fast, carefree, and professional service. Count on our certified repair team to ensure you invest all your free time enjoying your yacht, NOT working on it.

Onyx services are designed to make your experience on the water the best it can be.

We understand that boat maintenance can become time-consuming and a hassle at times. Our goal is to provide a fast, carefree, and professional service. Count on our certified repair team to ensure you invest all your free time enjoying your yacht, NOT working on it.

Request a Quote

How it Works!

How it Works!

An Onyx specialist will contact you within an hour after submitting a request. For time-sensitive issues or, if preferred, please call

An Onyx specialist will contact you within an hour after submitting a request.

For time-sensitive issues or, if preferred,

please call (786) 505-4259.

Onyx Yacht Painting

Onyx Yacht Painting

____________________

Protecting your investment in your yacht is a necessary part of owning a luxury vessel. Harsh saltwater conditions require a regular painting and coating treatment to keep your boat sailing on clear waters.

Painting/Maintenance options for your vessel include:

- Marine Paint (single or two-part)

- Gel Coating, Ceramic Coating, Bottom Painting, Varnishing and Carpentry

- Prop Speed Painting

Painting and Coating will breathe new life into your vessel. It will prevent damage to the hull and arrest the growth of marine organisms that attach to fiberglass and metal. Barnacles, algae, seaweed and other marine organisms accumulate on hulls and eventually lead to surface drag, lower performance, decreased speeds, higher fuel costs and even damage to propellors and other underwater mechanics.

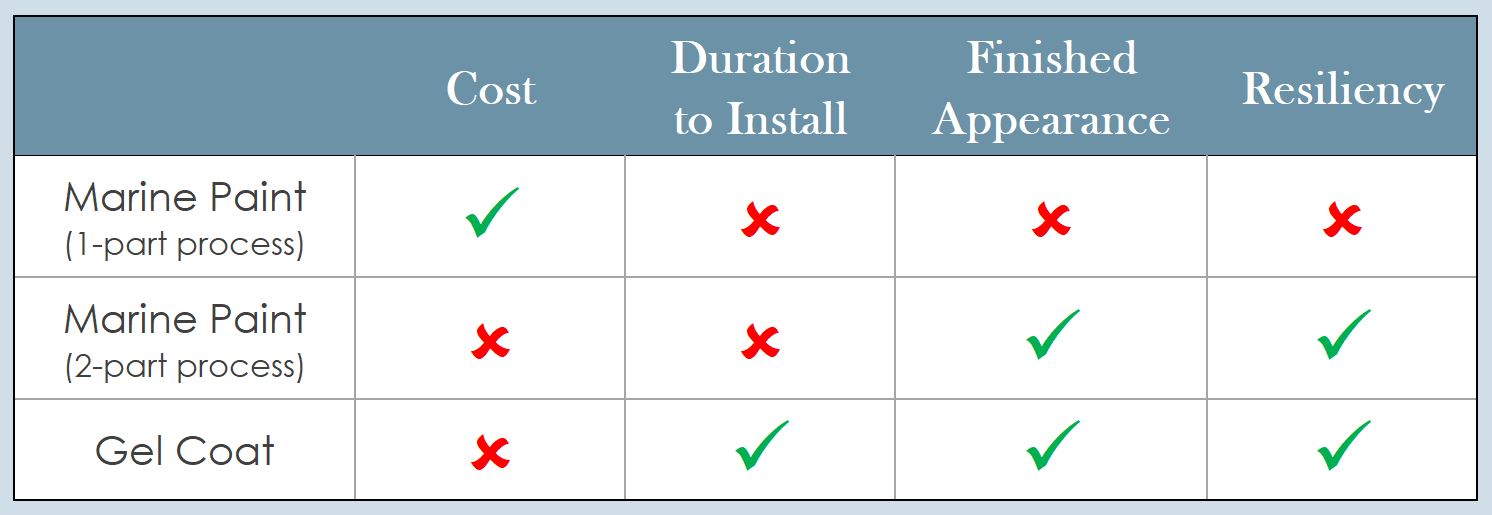

Our painting and coating solutions include modified epoxies, ablative, thin-film, soft and vinyl. Here is a rundown on the most popular options:

Marine Painting

When determining what paint/coating system is best for your vessel, the decision will come down to three elements: time, level of finish, and budget.

Traditional one-part paint (alkyd enamel) applies right from the dispenser and evaporates quickly. It has good weatherproofing qualities, and the base can be modified for gloss, hardness, or longevity by using various additives.

The two-part polyurethanes are formed by mixing components. That mix triggers a chemical reaction that forms the cure surface. When comparing the two processes, the two-part product dries quicker and offers a higher level of finish, a shinier gloss, color retention, hardness, longevity, chemical and abrasion resistance, and overall compound integrity. Consequently, the two-part process costs more and requires more time and labor.

Gelcoat Painting

A gel coat treatment is resin-based on often used on newly manufactured boats. Once applied, it dries into a hard, shell-like casing. Gel coating is designed to be UV protective and resistant to harsh chemicals. Since yacht hulls are often exposed to chemical vapors, this protection proves invaluable. A gel coat finish is durable and, when properly maintained, can last for decades without major repairs.

Ceramic Coating

Marine-grade ceramic coating is highly resistant to wear, scratching, and hull damage. The ceramic layer of protection protects paint and fiberglass. Ceramic coating protects at the molecular level with a comprehensive seal. Contaminants do not penetrate the surface, and any residue can be removed with a pH-neutral cleaner.

Bottom Painting

The bottom of a vessel, usually submerged in saltwater, is vulnerable to sea organisms, including acorn barnacles, zebra mussels, and microscopic bacteria that can cause hull drag, higher fuel costs and repair costs associated with the hull drag.

The correct yacht bottom painting treatment increases the longevity and performance of the vessel. The key ingredients in antifouling bottom paints include copper, biocides, algaecides, Teflon, vinyl, and proprietary two-part bottom coatings that create a hard, slippery biofilm that prevents organisms from attaching the hull.

Prop Speed Painting

One of the best ways to keep your props and other underwater metal in working order is by protecting them. One of the best ways is a professional application of Propspeed.

Propspeed uses a super slick “foul release” film that is safe for marine life. It is meant to last at least a year and keep running gear and any other underwater metals free of marine growth and protected against corrosion.

Vessels that sit in the water for extended periods have the greatest need for this type of protection. Our expert technicians can provide a professional application to protect your underwater metal.

Varnishing & Carpentry

Varnish Restoration

Onyx Yacht Detailing

& Maintenance

____________________

Onyx Yacht Detailing & Maintenance

Much a luxury car, your yacht boat needs regular detailing and maintenance work to keep it sparkling on the seas and humming along the waves. Detailing and maintenance include exterior boat detailing, washing, boat waxing, buffing, polishing, interior detailing, and monthly systems check.

Buffing & Waxing vs Polishing

There is an ongoing debate on buffing and waxing your yacht versus polishing it. Though similar, the processes are different. In the trade, professionals use polishing compounds, manual polishing, and rotary machines to buff out scratches. Most craftsmen use powerful buffing and polishing tools to remove blemishes, scuffs, oxidation, and other imperfections. Waxing usually follows the buffing process. Polishing a vessel restores the “good as new” finish. Using a high-gloss polish delivers a brilliant shine.

Additional Options

Other options include wet sanding and high-speed buffing to give your vessel a showroom look and erase oxidation stains and minor scratches on fiberglass and Gelcoat surfaces. While we are making the vessel’s exterior shine, we also inspect the vessel from top to bottom.

Monthly Packages

Onyx offers three monthly packages, in addition to our one-time services:

STAINLESS CLEANING PACKAGE

This package offers Exterior Cleaning & Detailing services once every two weeks as well as weekly Cabin Cleaning & Detailing services.

DEEP SAPPHIRE CLEANING PACKAGE

This package offers weekly Exterior Cleaning & Detailing services as well as weekly Cabin Cleaning & Detailing services.

ONYX DELUXE PACKAGE

This package offers weekly Exterior Cleaning & Detailing services as well as Cabin Cleaning & Detailing services twice weekly. The interior detailing treats all hard surfaces, including appliances and restroom fixtures, floors, blinds and cabinets.

Systems Check

Our comprehensive Systems Check includes checking the following:

Our comprehensive Systems Check includes checking the following:

• Wiring

• Battery

• Alternator

• Belts

• Navigation Lights

• Interior/Exterior Bulbs

• Bilge Pumps

• Instrument Panels/Electronics

• Solar Panels

• Fluid Levels

• Heads

• A/C Units

• Wiring • Battery

• Alternator • Fluid Levels

• Solar Panels • A/C Units

• Bilge Pumps • Navigation Lights

• Belts • Interior/Exterior Bulbs

• Heads • Instrument Panels/Electronics

Onyx Yacht Repair

____________________

Onyx Yacht Repair

Sometimes, repairs to your yacht go beyond the superficial and fall into the substantiative repair category. These repairs include fiberglass boat repair, gel coat boat repair, marine upholstery, teak repair and renewal.

Our craftsmen are highly skilled in repairing damage to your fiberglass or gel coat surface, whether dinged on a pier or scuffed on the rocks. We can also return your marine upholstery to its original luster and even tackle repair and restoration to teak, a classic favorite in yachting circles. Our corporate skillset includes lift and haul-out, carpentry, hydraulics, air conditioning, electrical and complete interior and/or exterior reconstruction.